A review of Nano4Ev's virtual event

Originally due to launch in March 2020, this Nano4EVs (Nanomaterials for Electric Vehicles) webinar event featured four presentations from leading academic and industry speakers which were enjoyed by the virtual international audience with more than 120 attendees.

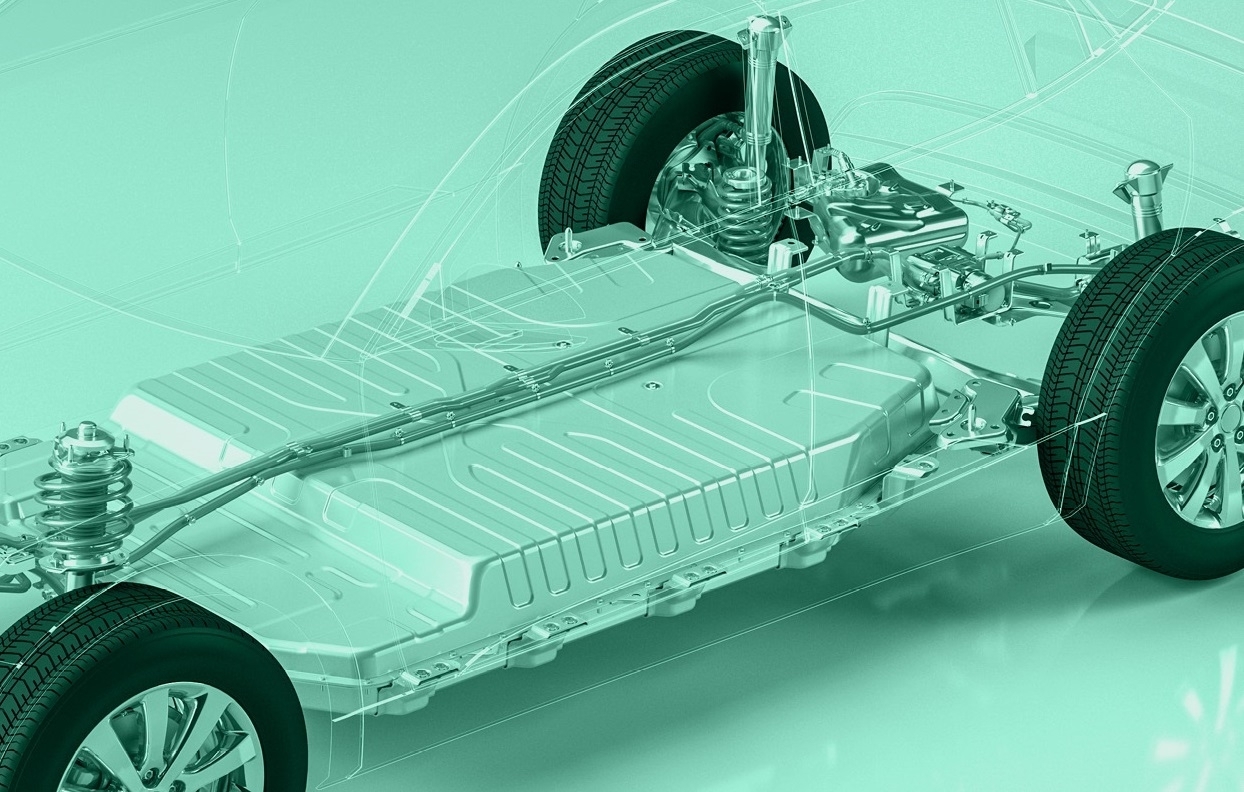

Organised by the IOM3 Nanomaterials Committee led by Dr Martin Kemp, who chaired this webinar. The event opened with an academic keynote from Prof Saiful Islam of the University of Bath entitled, 'Nanoscale Insights into Materials for Next-Generation Lithium Batteries.' Prof Islam's group use powerful materials modelling techniques linked to experimentation to develop new and improve battery chemistries. He acknowledged the performance drivers of fast charging and extended range, and the desire to replace cobalt. Prof Islam then briefly described the Faraday Institution funded CATMAT project that he leads, which seeks to develop next generation lithium-ion cathode materials with higher energy densities, for example manganese oxyfluoride materials based on disordered rock salt structures.

Next up was Denis Pasero, Technical Director of Ilika based in Southampton, who continued the theme of solid-state batteries, a technology which Ilika have commercialised. Ilika are cell developers, initially working on small battery cells for wearable devices and healthcare, and now tackling the challenge of scale-up to produce larger devices for battery EVs (BEVs). Ilika mainly use lithium nickel manganese cobalt oxide (NMC) cathode chemistry with solid ceramic oxide electroyte, but are also interested in polymer or semi-solid ceramic/polymer systems. Their battery anode is generally based on silicon and they are seeking to optimise particle size and mixture to reduce volume expansion issues. Work is also focussed on cell design and stacking optimisation, and they are aiming to achieve 400Wh/kg, work with the UK Battery Innovation Centre (UKBIC) on scale-up. A recent study they commissioned forecast a cell price in 2025 of US$60-65/kWh, and by 2030, US$50/kWh, and predicted that the UK BEV supply chain would be worth $5bn.

Ed Lester, Technical Director for Promethean Particles presented on 'Continuous Hydrothermal/Solvothermal Synthesis,' a 1000 tonne p.a. process which they have commissioned in 2016. The promethean process is an aqueous based process using both superheated and cold liquid streams to develop instantaneous nucleation of nanoparticles whose chemistry, size and morphology can be closely controlled. The process can make 2D, 3D and hybrid (coated) particle morphologies in chemistries including metals, metal oxides, doped metal oxides and MOFs. Typical markets in which their products are used range from printed electronics, inks and pigments, energy capture and storage, advanced coatings and healthcare. Promethean can make ithiated oxides and metal phosphates for battery electrodes, and materials for future devices that will be possible through multi-layer printing and sintering.

Dr Anna Wise, Head of Battery Technology at InnovateUK, presented on 'Nanomaterials for Energy Storage: Activity and Opportunities in UK R&D.' Dr Wise outlined that the Faraday Battery Challenge funding of £318m to March 2022 comprised the Faraday Institution, UKBIC and Collaborative R&D. The Faraday Institution co-ordinates academic research and has funded nine major projects, six on lithium ion, and these projects involve over 20 academic partners, and over 50 industry partners. The technical areas being funded include safety & diagnostics, cells & cell material, recycling & re-use; modules, packs, BMS and thermal issues. The UKBIC has received £130m in funding and is an open-access facility to de-risk scale-up. The Automotive Council and Advanced Propulsion Centre (APC) has developed a roadmap for vehicle electrification which highlighted areas for development. More recently, the British Standards Institute (BSI) has launched the first of a range of PAS standards under the Faraday Battery Challenge Standards Programme.

The webinar concluded with a Q&A session chaired by Prof Beverley Inkson of University of Sheffield and an enthusiastic audience including early career researchers asked some excellent, and sometimes challenging questions.

Dr Martin Kemp, Chair IOM3 Nano Committee

The next event will be Nano4EVs 2.0 which will be held as a virtual conference on 2–3 March and call for papers are now open.